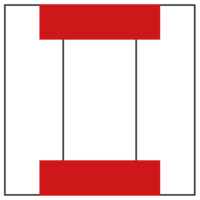

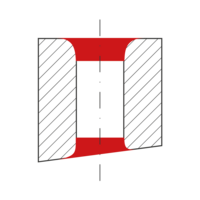

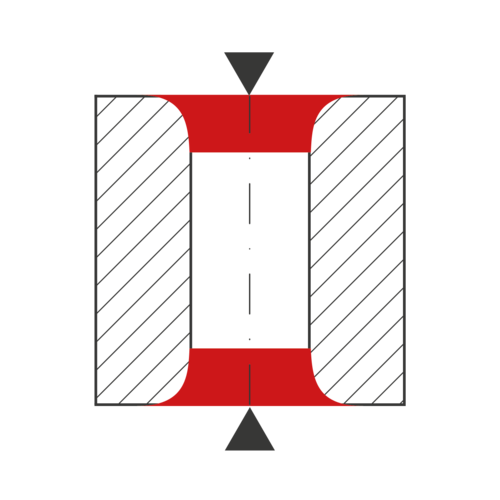

Uniform deburring on both sides in a single pass, without rotating the workpiece.

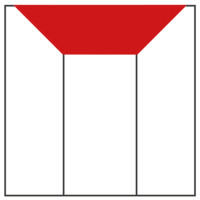

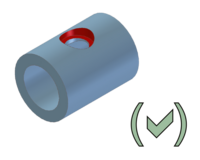

Economical forward and backward bore chamfering in a single pass.

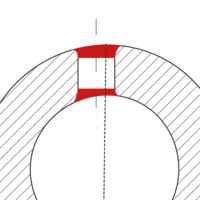

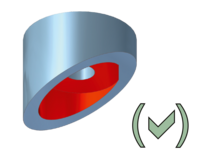

Back counterboring of bores without rotating the workpiece.

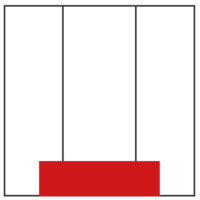

Economical drilling combined with deburring, chamfering or countersinking.

From bore diameter 2.0 mm: front and back deburring of even and uneven bores in one single pass

Bore diameter 1.0 mm to 2.1 mm: forwards and backwards deburring of even and slightly uneven bores in one single pass

Front and back chamfering of interrupted bores – even with large burrs – in one single pass

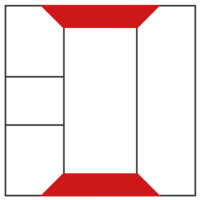

Front and back counterboring and backspotfacing in one single pass. Interrupted cutting possible

Solid carbide drilling combined with chamfering forwards and backwards in a single pass in the diameter range from 4.0 mm to 10.0 mm.

Your drill body combined with our chamfering module for simultaneous machining from bore-Ø 18.0 mm

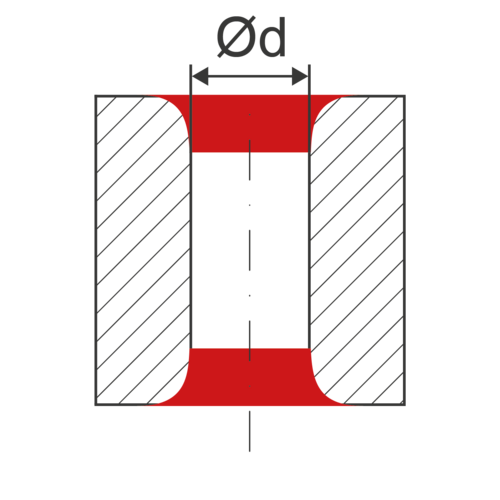

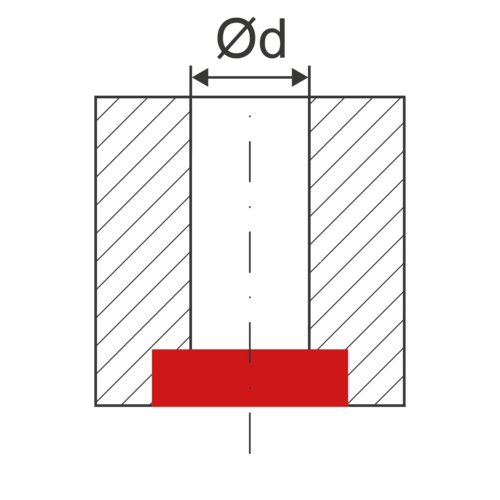

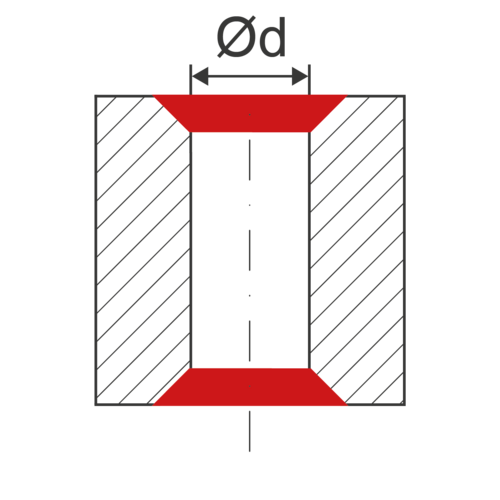

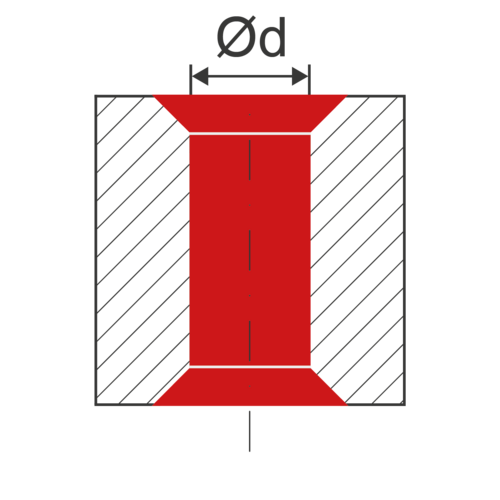

Choose a value between 2.0 mm and 26.0 mm. For smaller diameters please switch to DL2. For larger diameters, please contact HEULE.

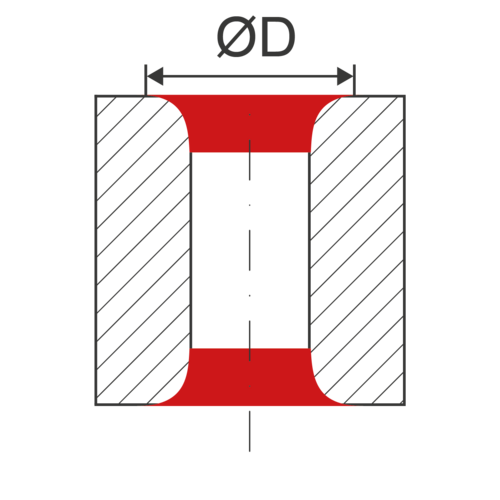

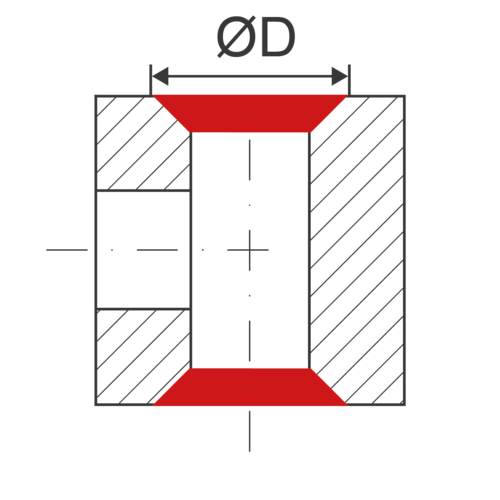

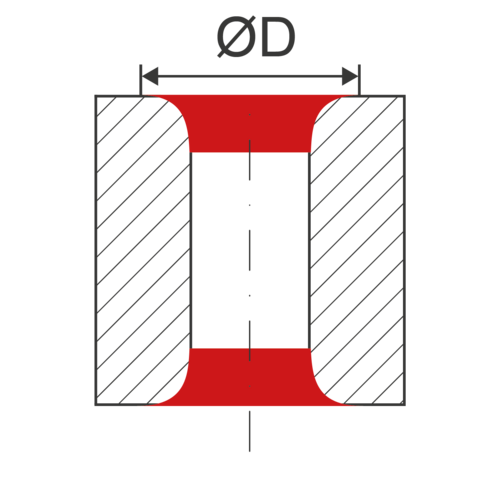

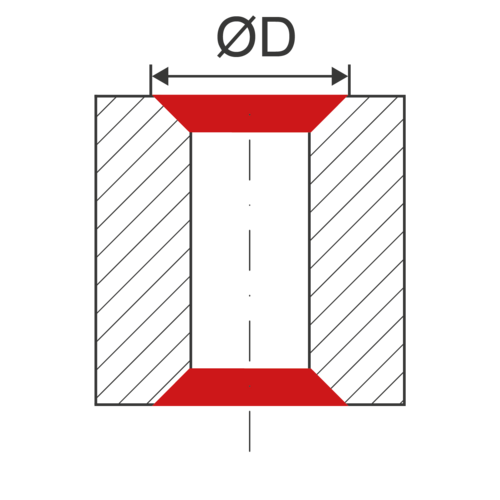

Choose the desired deburring diameter ØD.

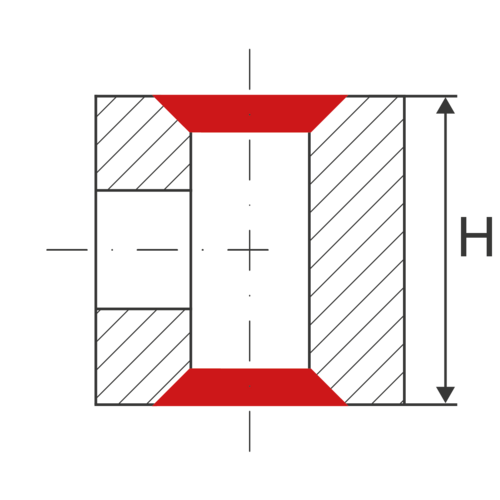

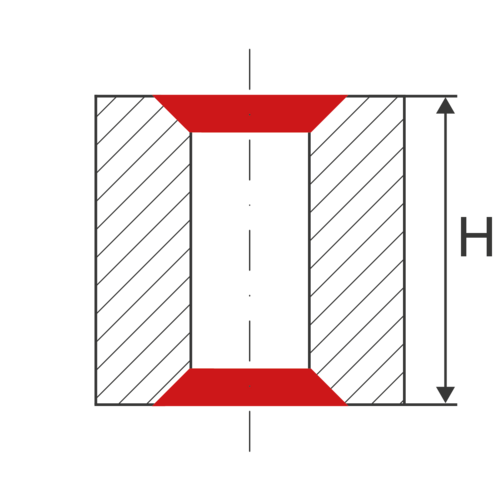

Enter the workpiece height H.

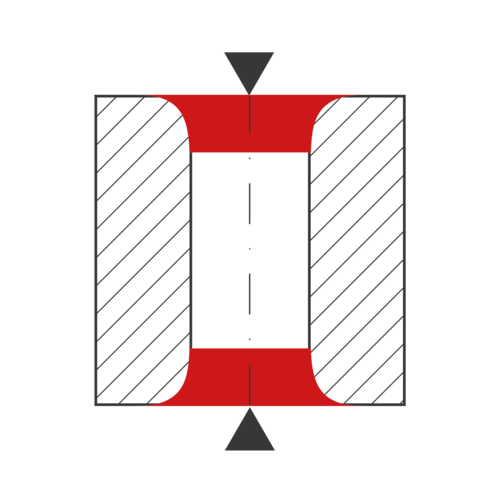

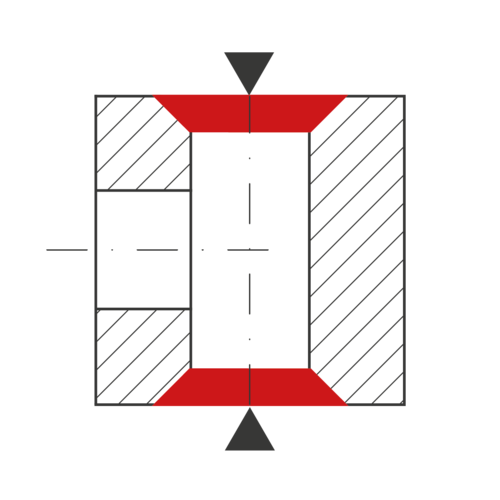

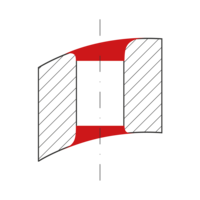

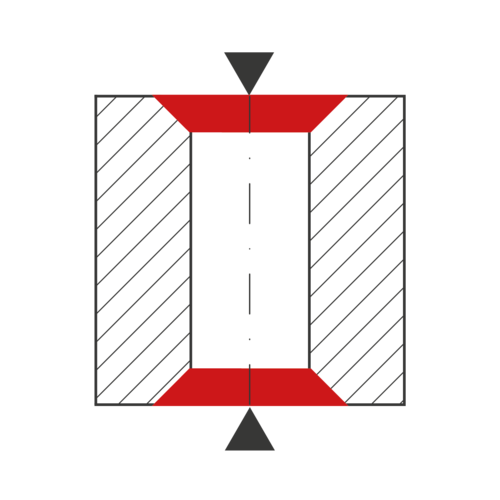

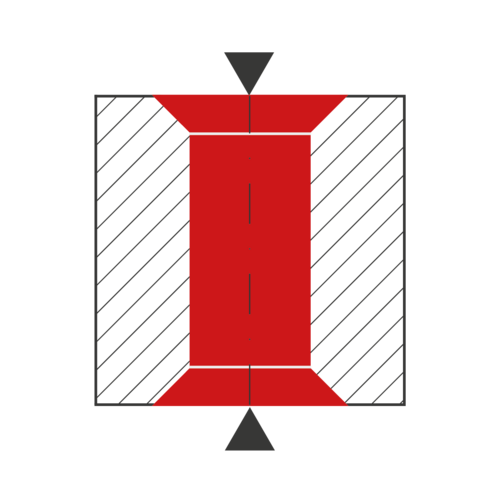

Choose the edge to process.

Choose the appropriate situation.

Enter your material or material group to determine the blade’s spring strength and coating of the carbide blade.

Choose a value between 6.5 mm and 21.0 mm.

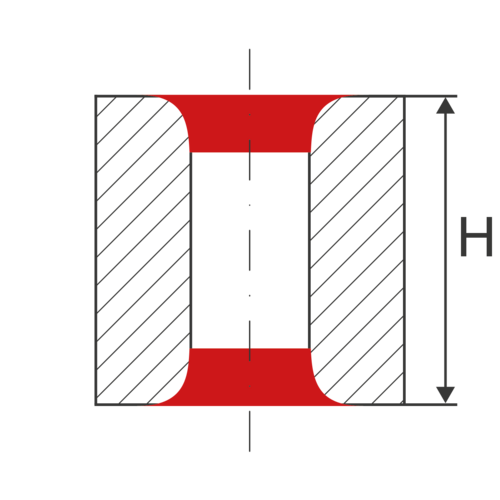

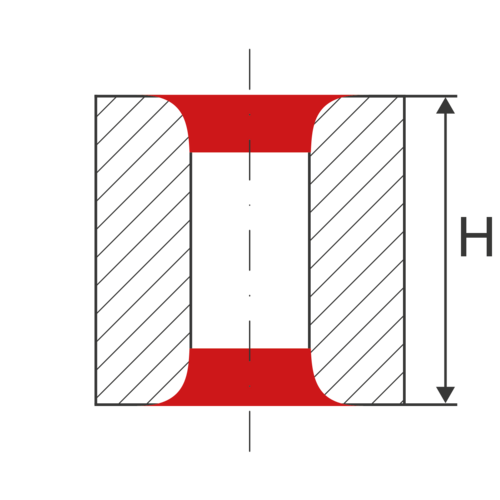

Choose the desired counterbore diameter ØD.

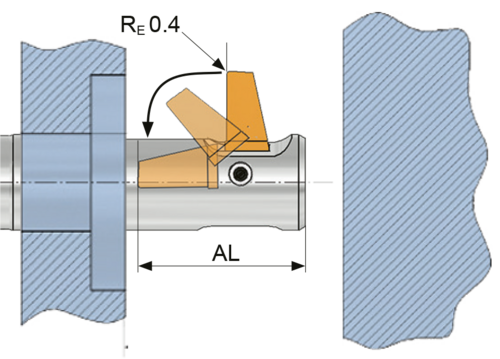

Choose the appropriate corner radius Rₑ.

The minimum swing length (AL) is given with the product proposal.

Enter the workpiece height H.

Choose the unevenness height of the processing surface.

Choose the desired tool activation for folding the blade.

Enter your material or material group to determine the carbide blade’s coating.

Choose a bore diameter range between 4.0 mm and 23.9 mm. For larger bore diameters please Contact HEULE.

Choose the desired chamfer diameter ØD.

Enter the workpiece height H.

Choose the edge to process.

Choose the shank style.

Enter your material or material group to determine the carbide blade’s coating.

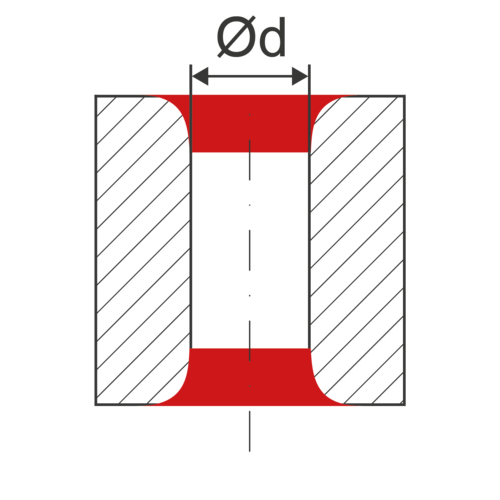

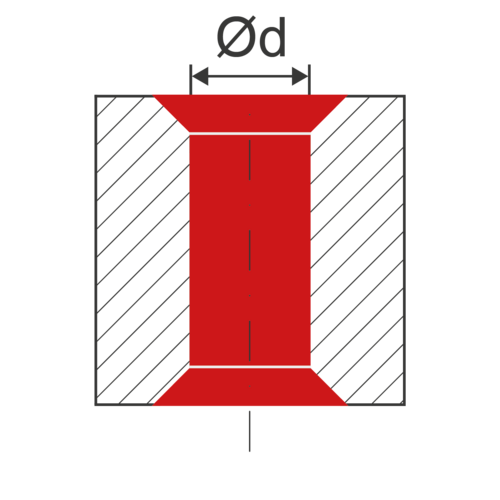

Choose a value between 1.0 mm and 2.1 mm. For larger bore diameters Ød please switch to COFA.

Choose the desired deburring diameter ØD.

Choose the appropriate situation.

Enter the workpiece height H.

Choose the edge to process.

Enter your material or material group to determine the blade’s spring strength and coating of the carbide blade.

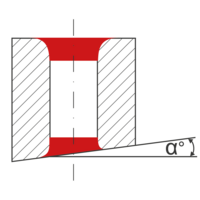

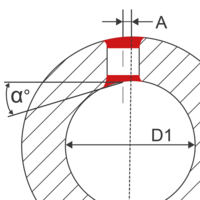

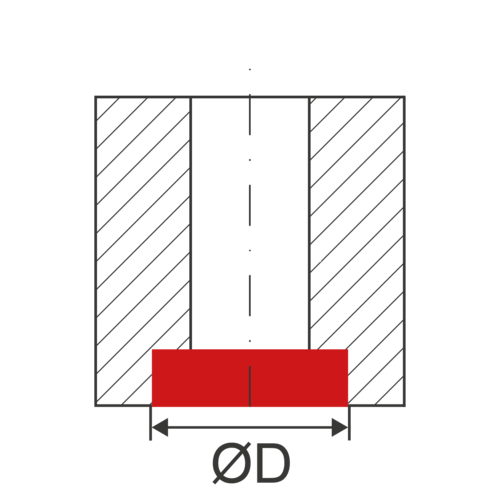

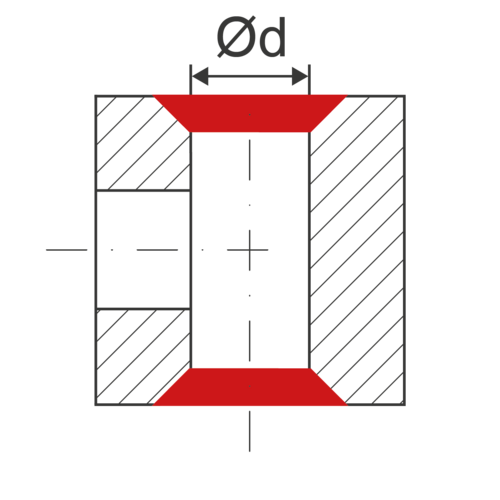

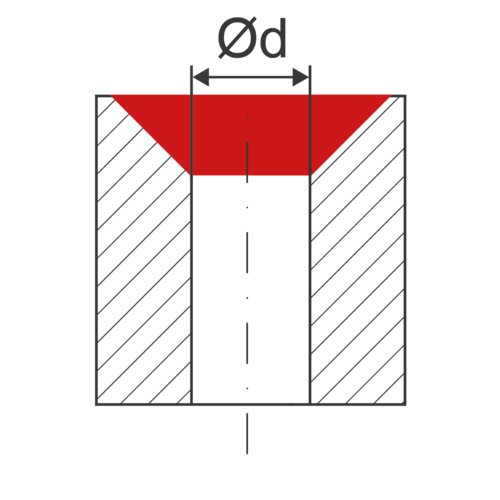

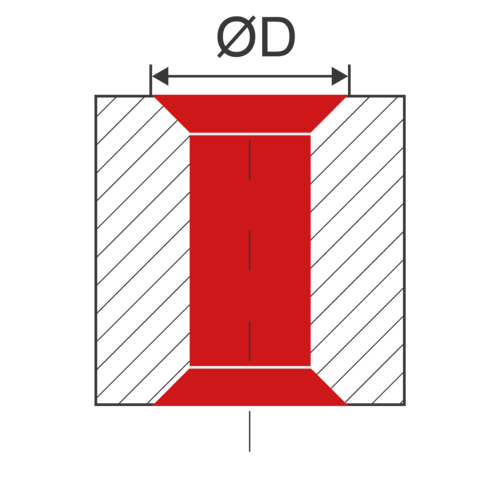

Choose your bore diameter Ød.

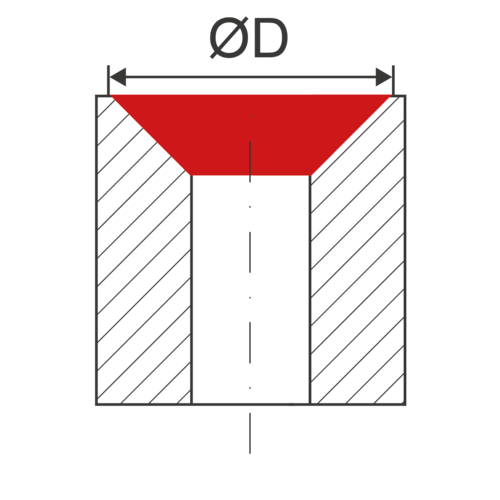

Choose the maximum counterbore diameter ØD.

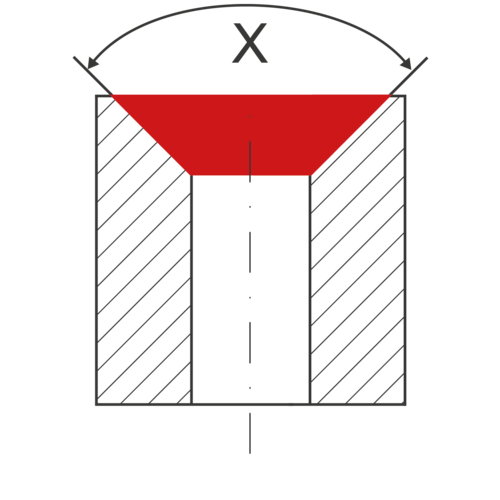

Choose the counterbore angle X.

Choose the desired number of blades.

Single cutters require a stable machine and workpiece clamping setup.

3 cutters allow higher working feed rates.

Enter your material or material group to determine the blade’s spring strength and coating of the carbide blade.

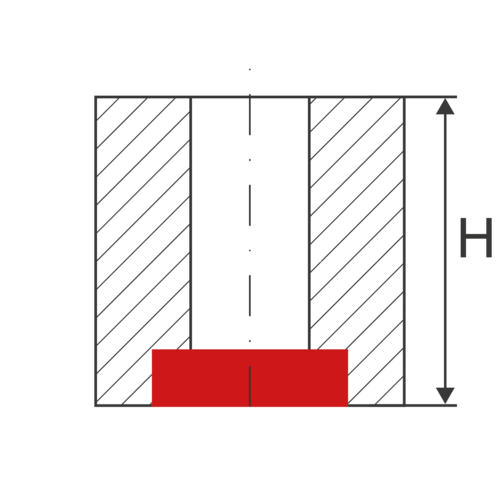

Choose a value between 2.0 mm and 37.5 mm. For smaller bore diameters Ød, please switch to DL2. For larger diameters please Contact HEULE .

Choose the desired chamfer diameter ØD. If the bore has a thread, please contact HEULE for a threading tool.

Enter the workpiece height H.

Choose the edge to process.

Enter your material or material group to determine the blade’s spring strength and coating of the carbide blade.

Choose the appropriate bore diameter range.

With IC: 6.0–17.00

Without IC: 5.0–11.49

Choose the desired chamfer diameter ØD.

Choose the edge to process.

Choose the desired bore diameter Ød for the drill tip.

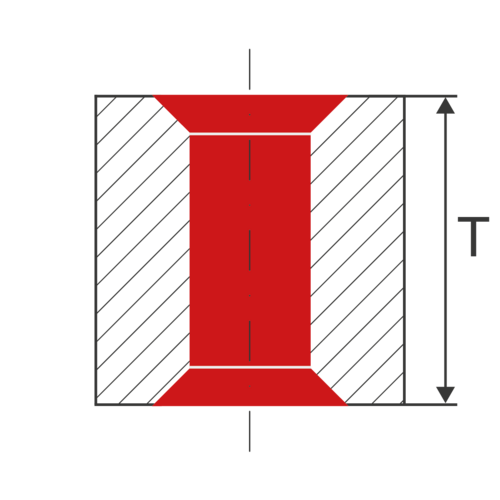

Choose the maximum drilling depth T.

Enter your material or material group to determine the blade’s spring strength and coating of the carbide blade.