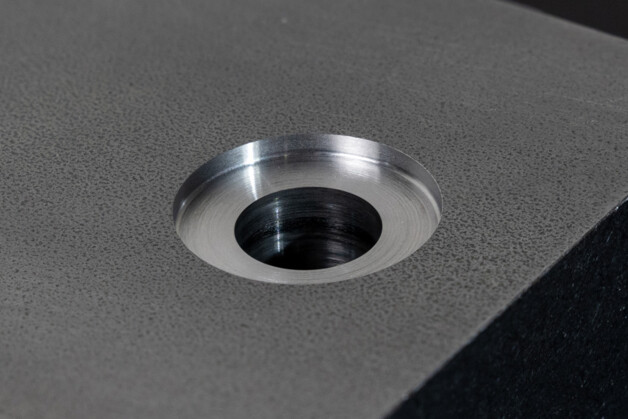

Deburring

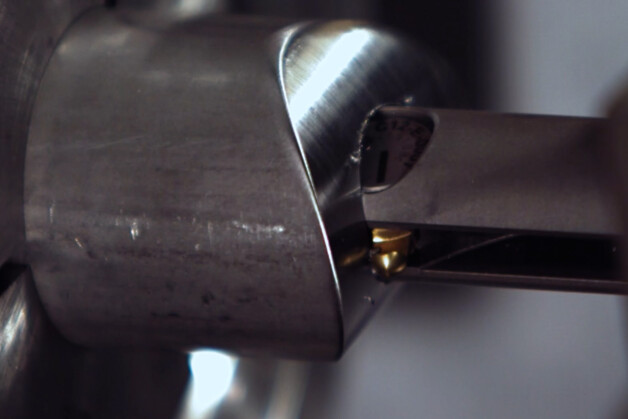

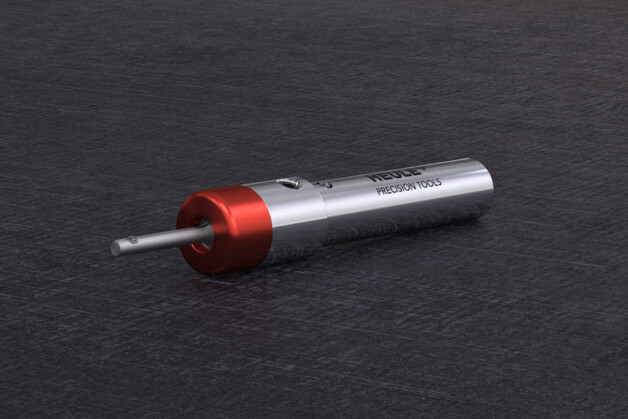

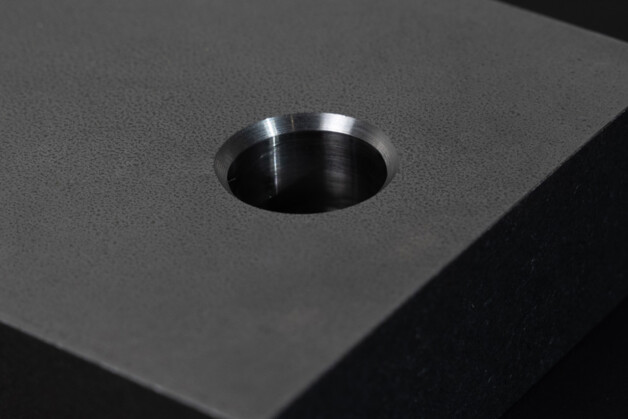

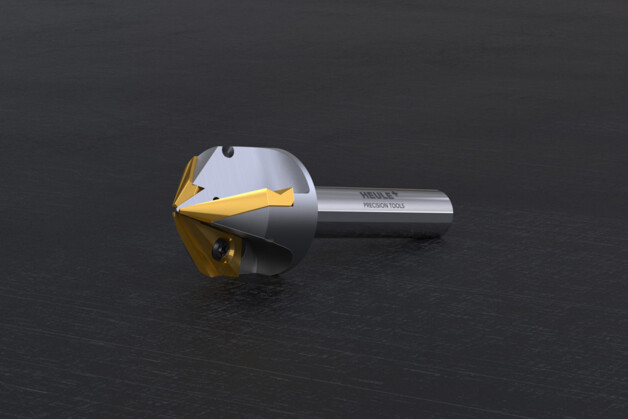

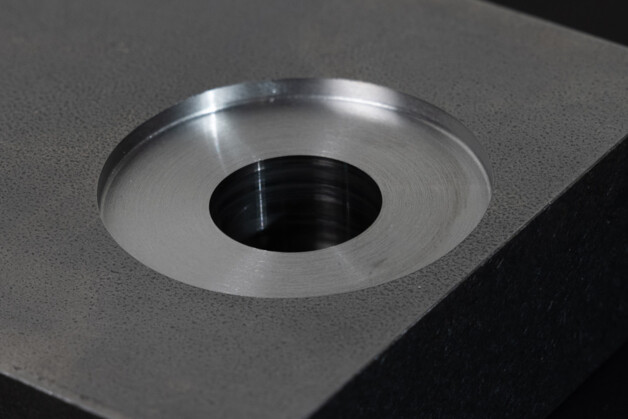

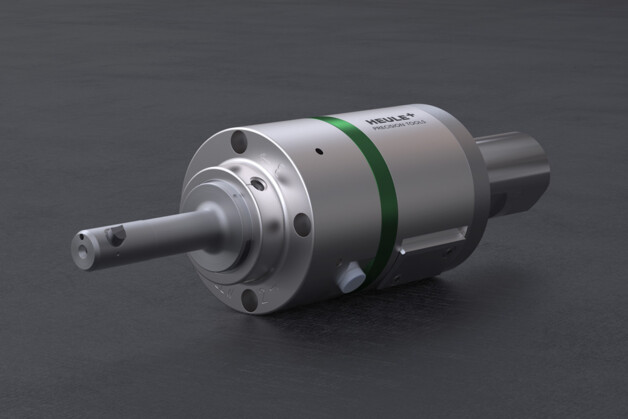

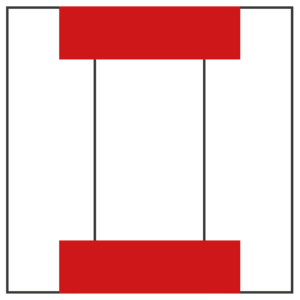

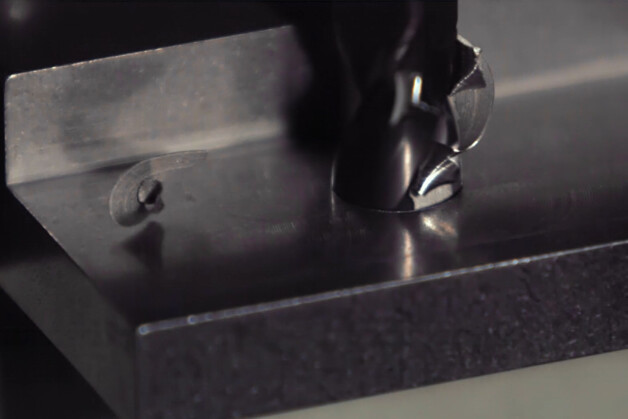

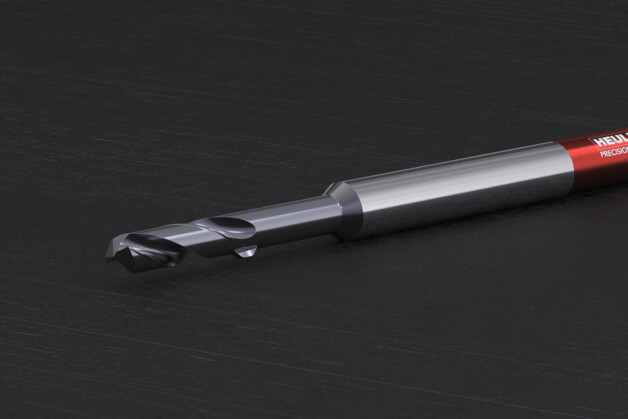

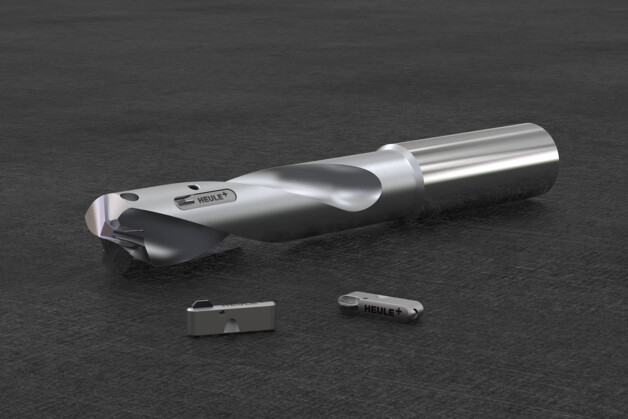

The HEULE deburring tools deburr even and uneven bore edges, front and back in a single pass, without the need to rotate the workpiece or stop the spindle. They are universally applicable for both manual and CNC processes.

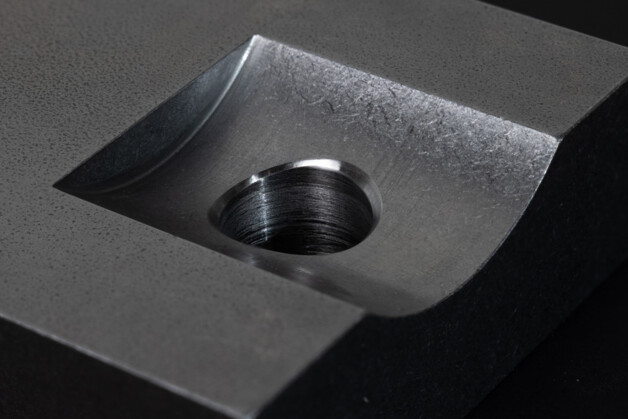

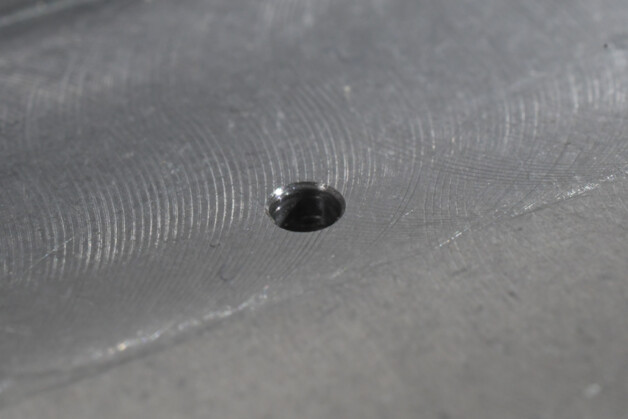

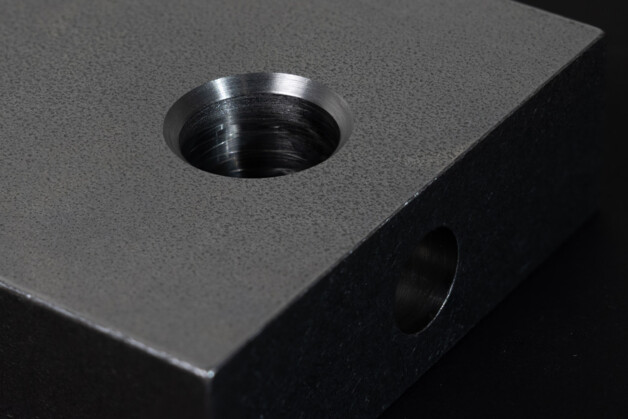

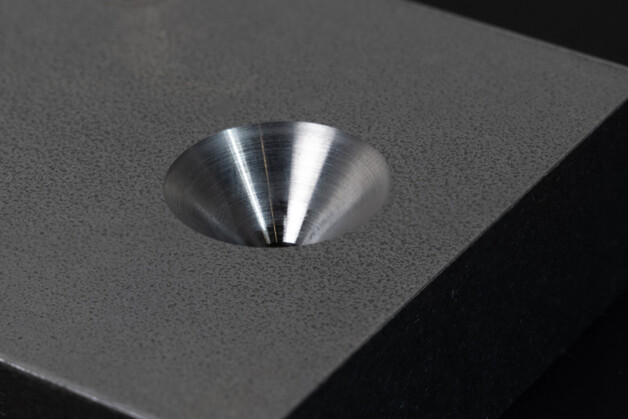

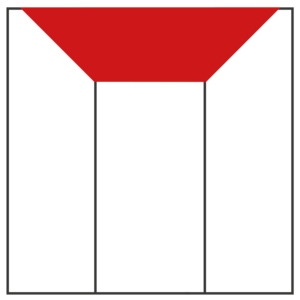

- Radius-shaped, consistent deburring result thanks to the defined cutting edge

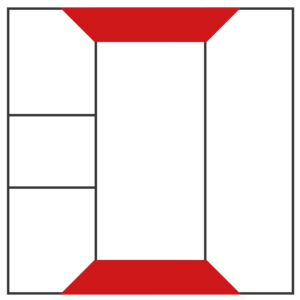

- Uneven surfaces up to 30°

- Typical deburring size of 0.2 – 1.4 mm

- Can be used from a bore diameter of 1.0 mm up to any size

- Can be used for aluminium to nickel alloys / coated carbide blades

- Simple tool concept and operating principle for safe handling