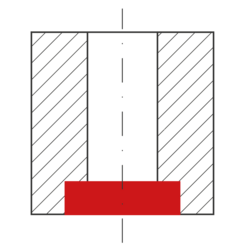

The tool is moved in rapid feed in front of the bore. When the internal coolant is activated, the pressure on the control bolt causes the blade to retract. Alternatively, the blade can be activated with air or by turning the manual activation ring. In this position, the tool moves through the bore. After turning off the internal coolant and activating the spindle rotation, the blade is extended. In working feed, the counterbore is now machined on the back of the bore. Once the blade is in the cut, the internal coolant can be switched on again.

Once the tool has reached the desired bore depth, the internal coolant is switched off. The tool is then removed from the counterbore and the spindle is stopped. The subsequent activation of the internal coolant ensures that the blade folds in again, allowing it to rapidly traverse out of the bore with activated internal cooling (if available).