DCC

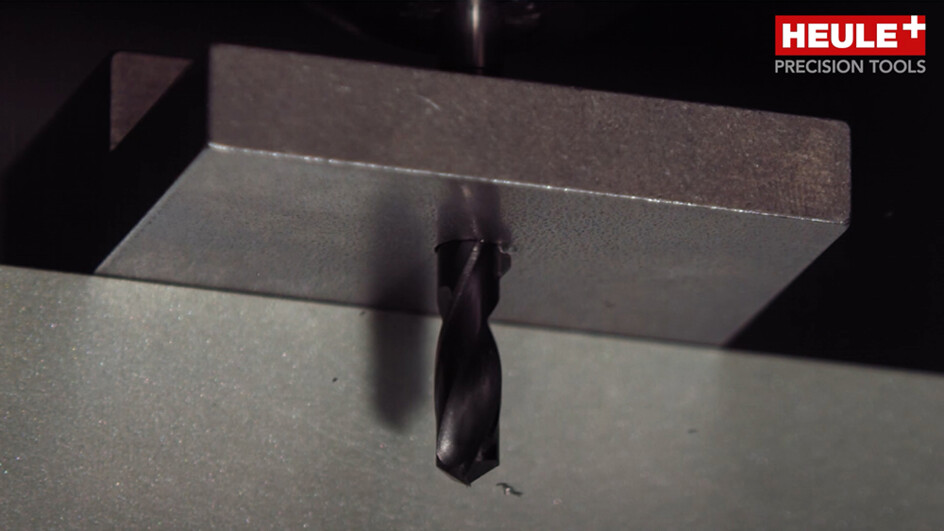

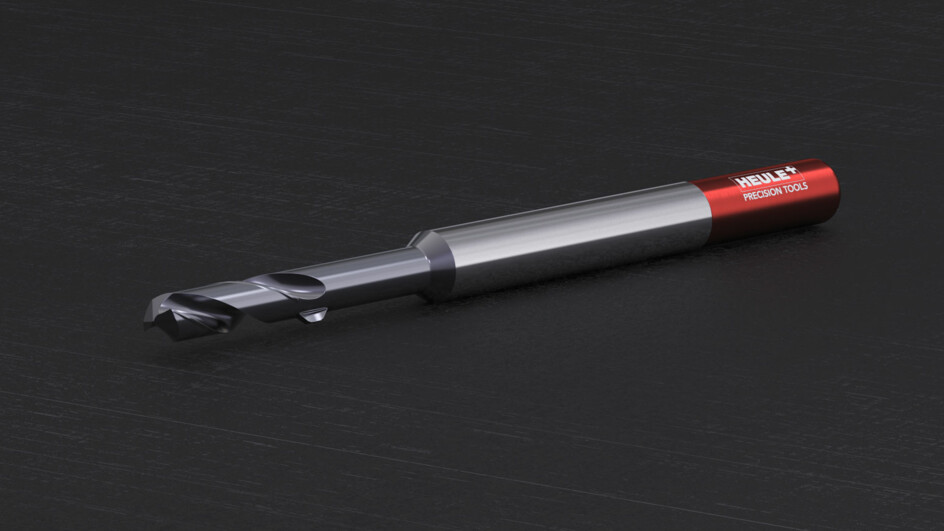

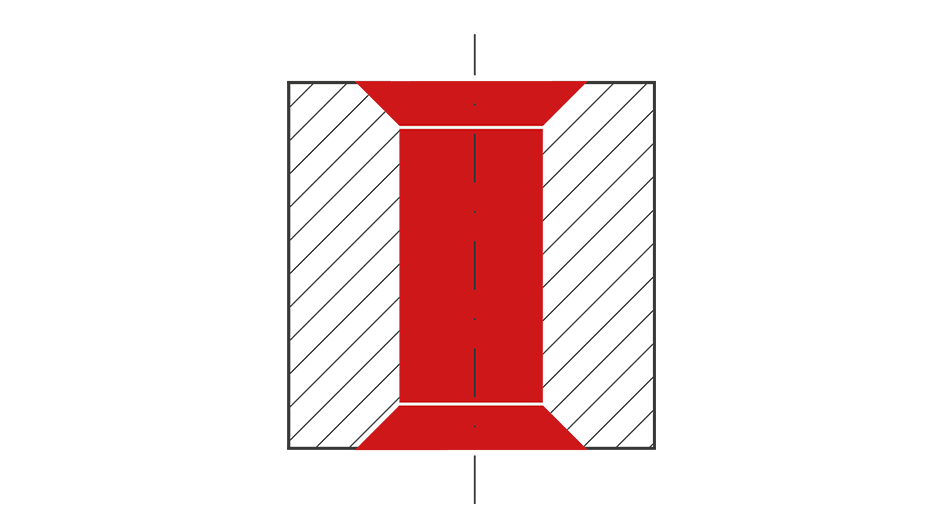

Solid carbide drilling combined with forward and backward chamfering in a single pass

- Drill Ø 4.0 mm - Ø10.0 mm, drilling depths up to 2.5 x drill diameter.

- All the advantages of a solid carbide drill bit.

- Short set-up and non-productive times thanks to simple handling

- Reduced process times thanks to processing in a single operation