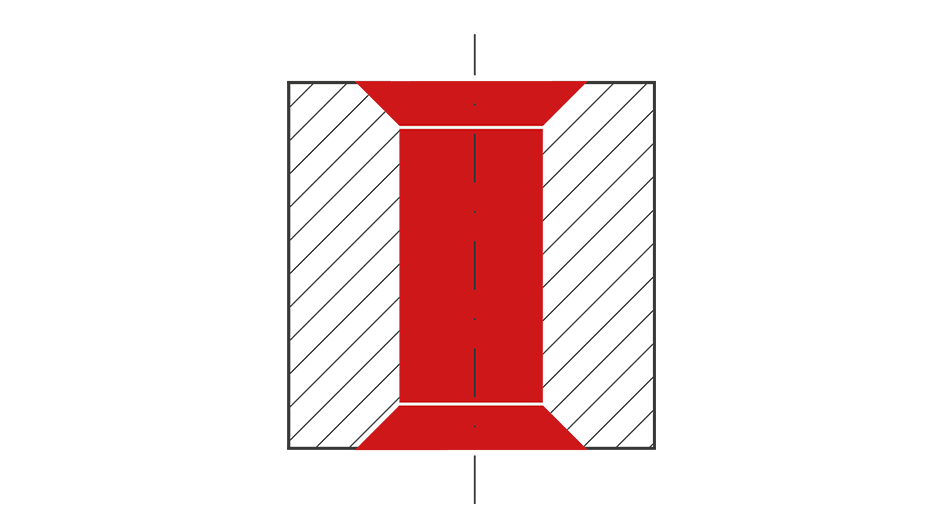

In a single operation, the bore is produced with chamfers on both of its edges. This process is completed without rotating the workpiece or changing tools.

The existing drill body is used for drilling. During drilling the integrated SNAP Module is used to chamfer the front and back edges. The desired chamfer is created by the blade in working feed. Upon reaching the defined chamfering size, the blade retracts radially into the tool body. When exiting the bore, the spring-loaded control bolt returns the blade to its neutral position so that the chamfer can be machined on the back edge of the bore.

The blade automatically retracts due to its geometry when the chamfering size is reached. Inaccurate workpieces such as castings with their typical tolerance variations can now be machined reliably and with a consistent chamfering result.